Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

- BOP Lifting Systems

- Liftchain Air BOP Handling System

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Durability

Safety

Performance

Using the right trolley size is crucial for your installation.

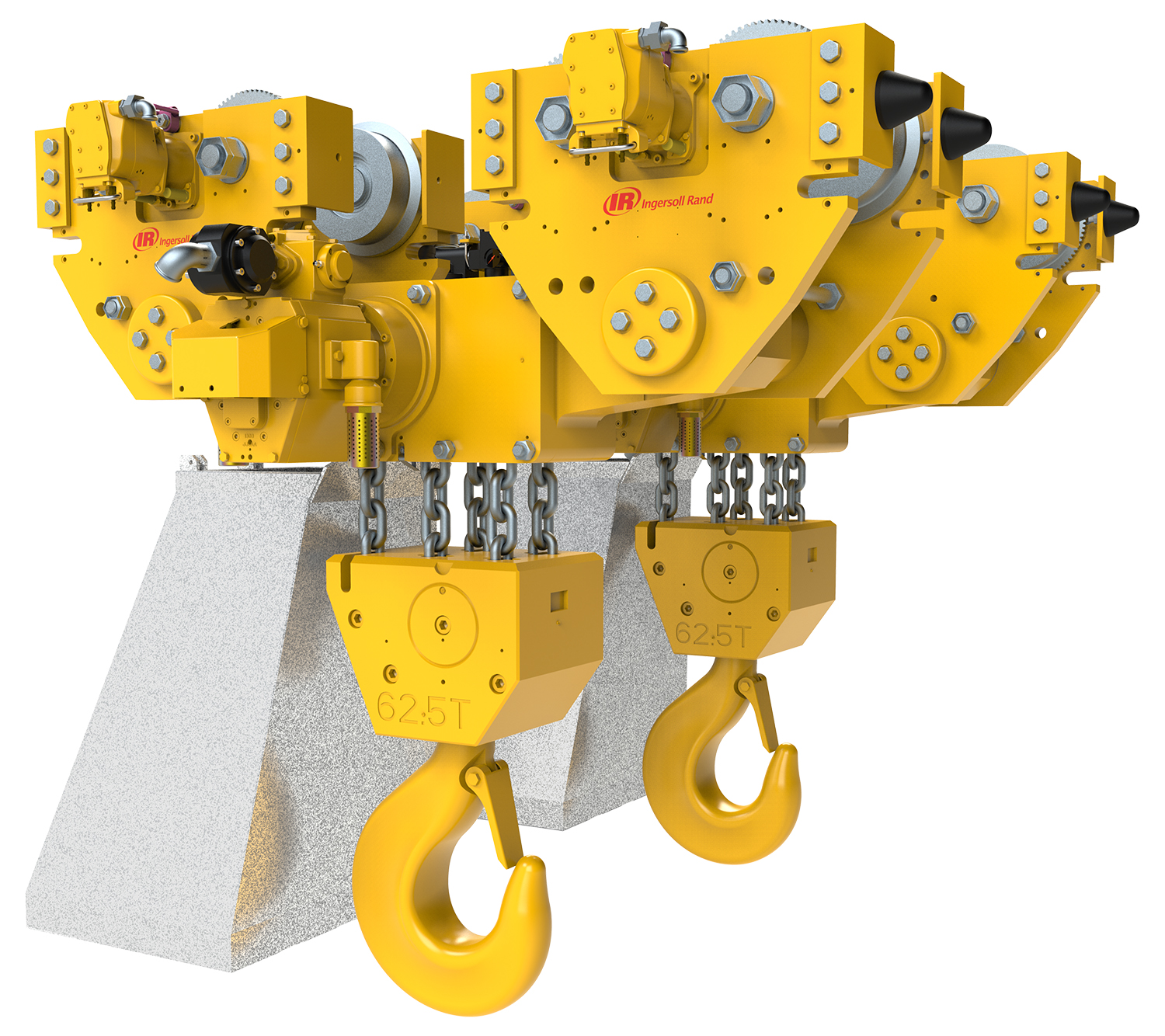

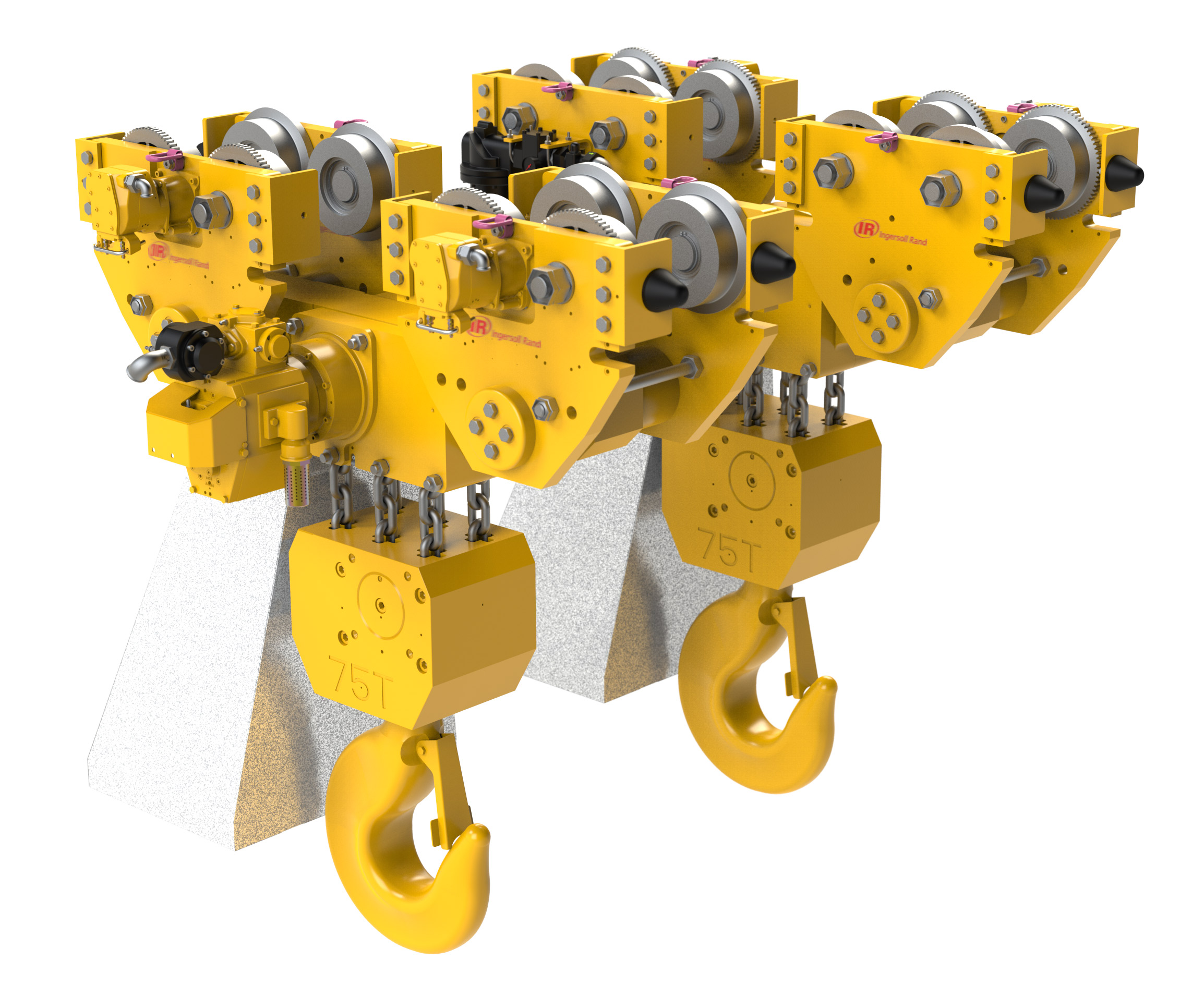

Ingersoll Rand has created two trolley sizes in order to match any configuration, even with large structural beams, for any specific situation.

To select the correct trolley size, you need to check if your theoretical beam size "Y" plus the clearance "E" on each side of the beam is compatible with the flange adjustment range "X" shown in the standard Model Specifications tables.

For very large beams, an optional wide beam flange adjustment (option "W") can be ordered. Please contact your Ingersoll Rand representative to order.

When the BOP system has to be installed on a bi-directional bridge crane, the PHS6 pendant allows full control of the 3 movements. The progressive control levers provide an exceptional variable speed control of the load. Various versions are available to meet CE and ATEX requirements.

PHS6E-U Pendant, CE Version

The Accu-trol™ pendant is an alternative to the standard PHS pendant, offering a vertical arrangement of the control buttons in a fully enclosed impact resistant frame. Available with up to three functions (6 motions), and optional emergency stop button with CE version.

Accu-trol Pendant,

Non-CE Version

Ingersoll Rand can also offer a standing control console for remote control of 2 or more hoists. From the instrument panel, each hoist can be run individually and an additional joystick allows the operator to simultaneously control a group of hoists. Emergency stop buttons are fitted as standard on CE versions

Ingersoll Rand has delivered many wireless control systems to customers with specific features to match their applications.

Wireless Controller

Air hose kits of different sizes and lengths can be ordered with your hoists system to create a supply line. The kit includes the high quality hose and end fittings to connect to the hoist inlet and the supply source.

Festooning trolleys will support the air hose on the travelling beam; number of trolleys has to be determined with your Ingersoll rand representative depending on the travel length and the loop height.

Specific models are available for ATEX zone 1 areas.

When harsh conditions are met in offshore operations, our Rack & Pinion drive system offers a positive engagement. Rack sections of 1.5 meters long have to be welded on the travel beam. The positioning underneath the beam flange prevents dust contamination and ensures long life.

This additional hanging point on the hoist trolley assembly allows for suspending the BOP stack for storage. While using the retention lug, the hoist drive and brake mechanism are not subject to vibrations under load tension. Light maintenance operations can also be performed on the hoist while the BOP is secured using this lug.