Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Customized Lifting and Pulling Solutions

Dynamic industrial operations are rarely serviced by a blanket approach.

Our Customized Lifting and Pulling solutions address specific challenges faced by our clients in their day-to-day operations.

How does it work?

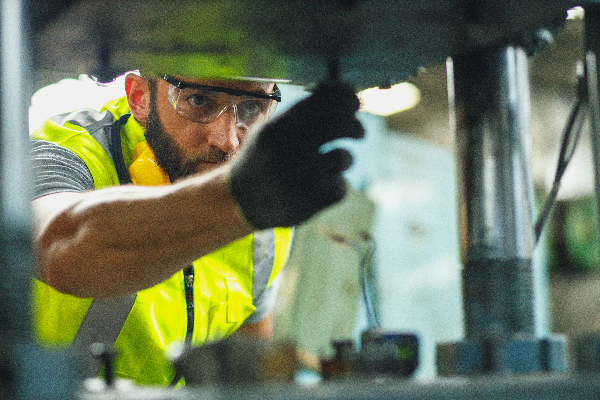

Our engineers have the technical expertise to customize any of our standard equipment to meet and exceed our client’s bespoke needs.

Whether it is the customization of existing equipment or the design of entirely new solutions, our team works around the clock to provide tailor-made products and services that integrate seamlessly into our clients’ specific operational environments.

Partner with Ingersoll Rand

Ingersoll Rand values quality, reliability, and safety as part of our core values. We vow to provide our customers with the highest quality, expertise and safety in every product and service we offer.

Our customized material handling solutions are designed to meet our customers’ unique needs, helping them to achieve operational excellence across all industries, environments and challenges they might come to encounter.

Contact Us Today

Ready to elevate your operations with customized solutions? Our team is here to accompany you in reaching your goals for operational efficiency, safety and excellence. Contact us now.

Why Choose A Custom Solution?

Customization

Receive equipment tailored to meet your specific needs.

Efficiency

Benefit from optimized solutions that enhance productivity and reduce operational costs.

Expert Support

Collaborate with our team of experts throughout the design and implementation phases.

Reliability

Access our unique lifting and pulling solutions engineered to perform under your specific conditions.

About Ingersoll Rand

For over a century, Ingersoll Rand has been a global leader in industrial solutions, delivering high-quality products and services that enhance efficiency and productivity.

Our commitment to innovation and excellence has made us a trusted partner to our clients and distributors across various industries worldwide.

Quality and Reliability

At Ingersoll Rand, quality is not just a goal, it is our standard. Our products are engineered to withstand the most demanding operational environments, ensuring long-lasting performance with minimal downtime.

We employ cutting-edge technologies and rigorous testing protocols to deliver solutions that meet and exceed not only our clients’ needs but also international industry standards.

Safety First

Safety is at the core of our mission and values. We design our products to the highest regulatory and technical standards, prioritizing the protection of our clients' workforce as well as their operational excellence.

Our dedication to safety allows companies to operate with confidence, knowing that our equipment is engineered to prevent accidents and enhance operational security and safety.

A Legacy of Excellence

With expertise and technical know-how cultivated since the 19th century, Ingersoll Rand has a strong legacy rooted in innovation and customer-centric solutions.

Over the decades, we have expanded our expertise and global reach to become synonymous with trust and reliability across all industrial sectors.

Industry Case Studies

Explore how our customized solutions have made a difference in various industries:

OIL & GAS

Boosting Efficiency in Offshore Drilling Environments

Our customized pneumatic chain hoists have played a critical role in removing existing pipeline values and installing replacement units. Our solution features Zone 1 ATEX (spark resistance) specifications and offers cross-hauling capabilities of up to 20 degrees, with a lifting height exceeding 15 meters.

MARITIME & SHIPYARDS

Navigating Success with Technical Customization

We provided a customized production barge which played a pivotal role in reconstructing Monaco’s harbor. It is equipped with pneumatic hoists and air-driven winches to support lifting underwater metal structures and cables.

MINING

Digging Deeper with Innovative Solutions

Our tailor-made mining equipment enabled the lowering and lifting of people and equipment down a 650 feet (198 meters) mineshaft, operated entirely by electricity, featuring an intuitive push-button control panel.

INDUSTRIAL LIFTING

Lifting Quality

By creating the double-drum waterfall configuration, we developed a system that not only responded to our customers' specific needs but also offered a blueprint for other companies facing similar lifting challenges in the field of constructions. The deployment of this solution demonstrates our commitment to integrating engineering excellence with practical design, resulting in equipment that guarantees safety, efficiency, and operator comfort.

Ready to elevate your operations with

customized solutions?

Our team is here to accompany you in reaching your goals for operational

efficiency, safety and excellence. Contact us now.